Virginia Industrial Finished Part

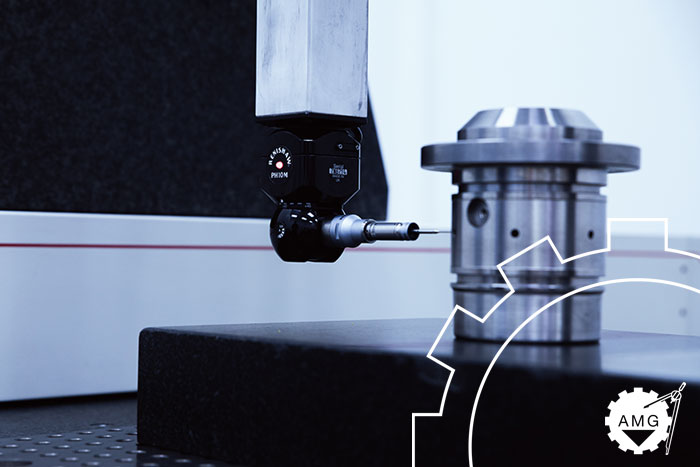

Inspection Services

We understand the importance of accurate inspection for ensuring that our customers’ machined parts meet the highest standards of quality. That's why we invest in advanced inspection equipment and techniques to ensure all parts are inspected to the highest levels of precision. As a result, our quality is second to none.

With our trained staff and controlled environment, we have the capability to record measurements to .0001” for our customers. AMG also offers its Inspection Department as a contact service.

Our Quality and Final Inspection Capabilities

We offer a range of inspection equipment and capabilities, including:

- Coordinate Measuring Machines (CMMs): Our CMMs use advanced software and scanning technologies to precisely measure the dimensions and geometries of parts, ensuring that they meet our customers’ exact specifications.

- Optical Comparators: Our optical comparators use advanced optics and lighting techniques to accurately compare parts to the original design specifications.

- Surface Profilers: Our surface profilers use advanced sensors and scanning technologies to precisely measure the surface roughness of parts, ensuring that they meet the required surface finish specifications.

- Digital Height Gauges: Our digital height gauges provide precise measurements of a part’s height and dimensions, ensuring that the part meets the exact specifications.

- Other Inspection Equipment: We offer a variety of other inspection equipment, including bore gauges, thread gauges, and hardness testers, to ensure that all parts meet the highest levels of precision and quality.